Contact us

EN

Language:

EN

Contact us

Step 5. 3D Printing

How does the printing process work and what is needed for the best result?

The process of printing parts on an SLM machine

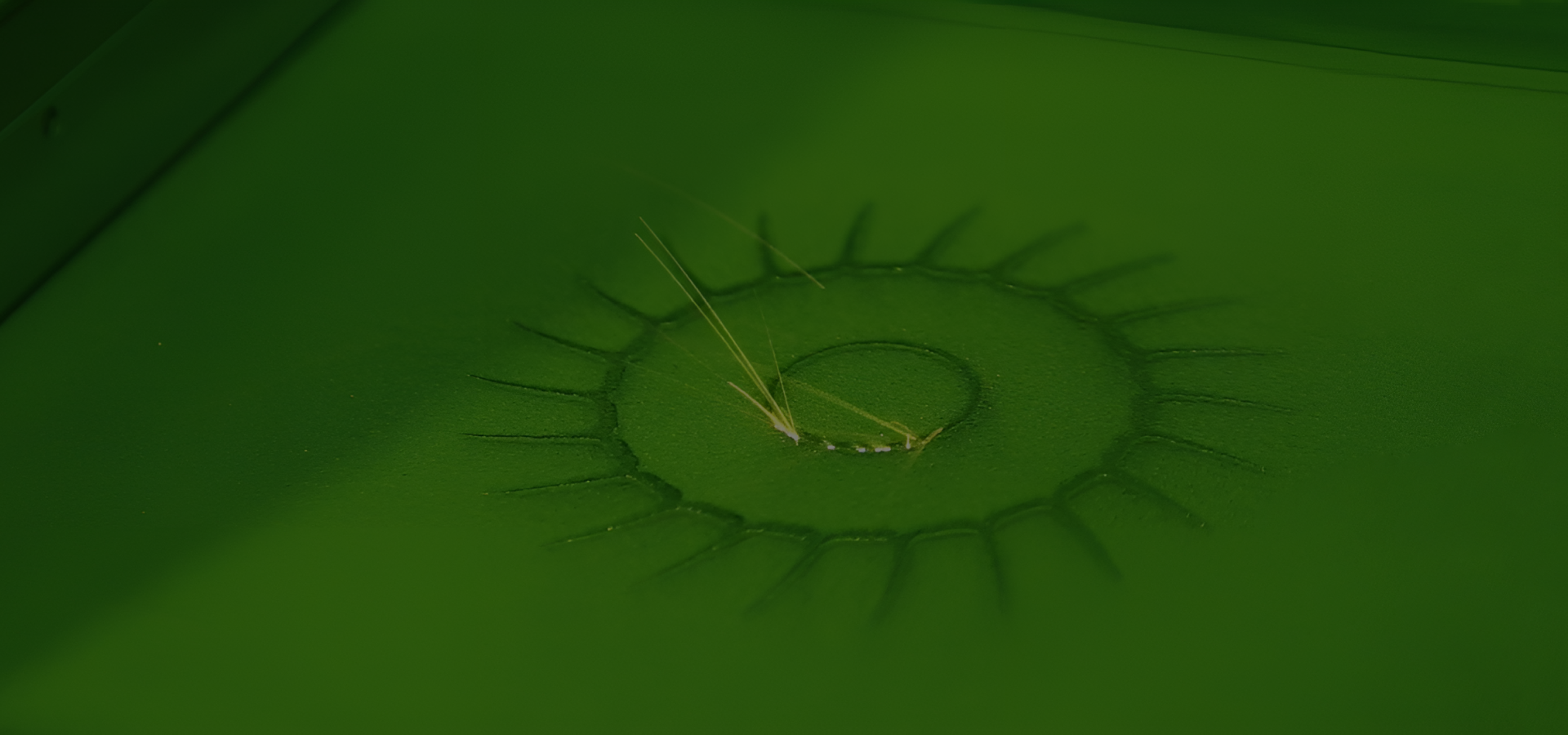

The recoater applies a thin layer of metal powder to the working area. Through the use of mirror systems, laser beams are directed onto the powder layer, selectively fusing it within the specified boundaries. This creates one layer of the part.

Next, the platform is lowered down by the thickness of the printed layer. Each layer is printed in the same plane. This process is repeated until the printing is complete: powder - laser radiation - lower, and so on.

The use of SLM 3D printers significantly reduces the number of steps in production. Traditional manufacturing methods often require a long time for the development and production of complex parts, as well as significant financial investments in equipment, tools, and labor resources. SLM 3D printing technology allows for process optimization, saving costs and time

Next, the platform is lowered down by the thickness of the printed layer. Each layer is printed in the same plane. This process is repeated until the printing is complete: powder - laser radiation - lower, and so on.

The use of SLM 3D printers significantly reduces the number of steps in production. Traditional manufacturing methods often require a long time for the development and production of complex parts, as well as significant financial investments in equipment, tools, and labor resources. SLM 3D printing technology allows for process optimization, saving costs and time

We will help you understand the subtleties for better results

Since the parts are printed layer by layer, an important characteristic of the printer is the accuracy of the 3D printing. Accuracy depends on the 3D model, the quality of the material (powder) used, the correctly selected printing parameters, and layer thickness. Parts from 3DLAM 3D metal printers achieve a 10th-grade accuracy level.

To achieve the best results, it is important to follow certain operating conditions of the setup and correctly configure the printing settings. We will explain and demonstrate how to do this during the basic training.

Moreover, we will stay connected even after the purchase to assist in solving tasks and answering questions of any level of complexity

To achieve the best results, it is important to follow certain operating conditions of the setup and correctly configure the printing settings. We will explain and demonstrate how to do this during the basic training.

Moreover, we will stay connected even after the purchase to assist in solving tasks and answering questions of any level of complexity

Please send your inquiry to learn more about our SLM 3D printers

Do you have any questions about our printers or contract printing services? Our knowledgeable specialists will promptly answer all your inquiries

Step 6

Post-processing

Areas of application

Learn about the advantages of metal 3D printing for various manufacturing sectors

Catalogue

Our solutions for SLM 3D printing

Learn more!