Contact us

EN

Language:

EN

Contact us

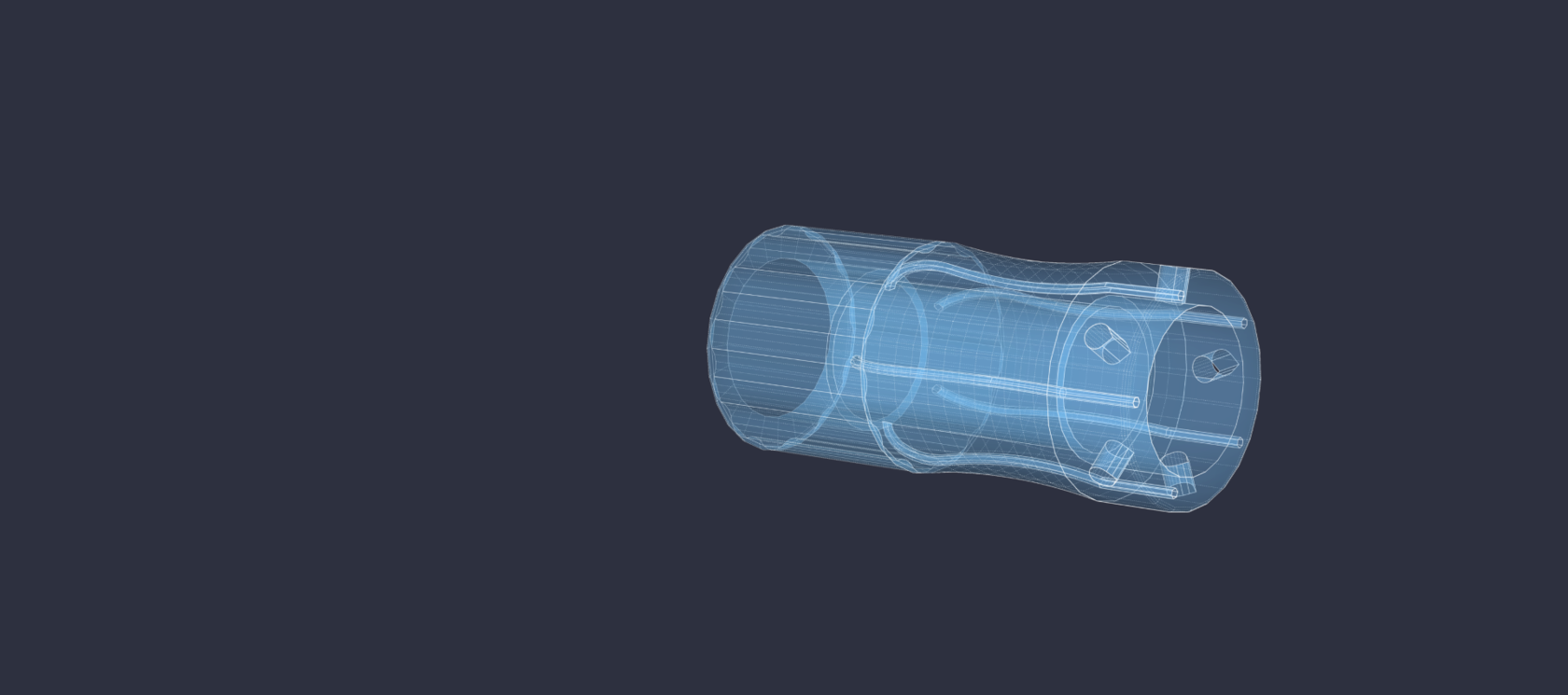

Step 1. 3D Model

3D printing is becoming increasingly popular in many industries. Preparing a 3D model for printing is an integral part of this process

Software used for developing 3D models for metal 3D printing

A 3D model for printing on an SLM machine is created using software designed for solid-state or polygonal modeling. For instance, software such as AutoCAD, SolidWorks, Blender, 3D Max, Fusion 360, COMPAS and others can be used.

Each software package is suitable for specific tasks. Some programs are better suited for assembly modeling, complex parts, or sculpting.

In addition to modeling, the software for working with 3D models allows for conducting aerodynamic and hydrodynamic tests, simulating the physical environment

Each software package is suitable for specific tasks. Some programs are better suited for assembly modeling, complex parts, or sculpting.

In addition to modeling, the software for working with 3D models allows for conducting aerodynamic and hydrodynamic tests, simulating the physical environment

Adapting a 3D model for printing on an SLM 3D printer

To print a part from a 3D model, we must adapt it for SLM manufacturing. To do this, we place "supports" in the model - thin supports that hold the overhanging parts of the product. Then we save the model in .step or .stl format

In the case when the supports cannot be extracted from certain parts of the design, we recycle some of the component parts of the part. For example, a channel or a pipe can be made with a drop-shaped cross-section, so that the element works as a stiffener and the product does not "hang" from the temperature

In the case when the supports cannot be extracted from certain parts of the design, we recycle some of the component parts of the part. For example, a channel or a pipe can be made with a drop-shaped cross-section, so that the element works as a stiffener and the product does not "hang" from the temperature

Please send your inquiry to learn more about our SLM 3D printers

Do you have any questions about our printers or contract printing services? Our knowledgeable specialists will promptly answer all your inquiries

Step 3

Raw materials

Step 4

What do you need to do to start the 3D printer?

Step 5

3D printing

Learn more!