Contact us

EN

Language:

EN

Contact us

Step 4. Preparing the SLM printer for printing

What do you need to do to start the 3D printer?

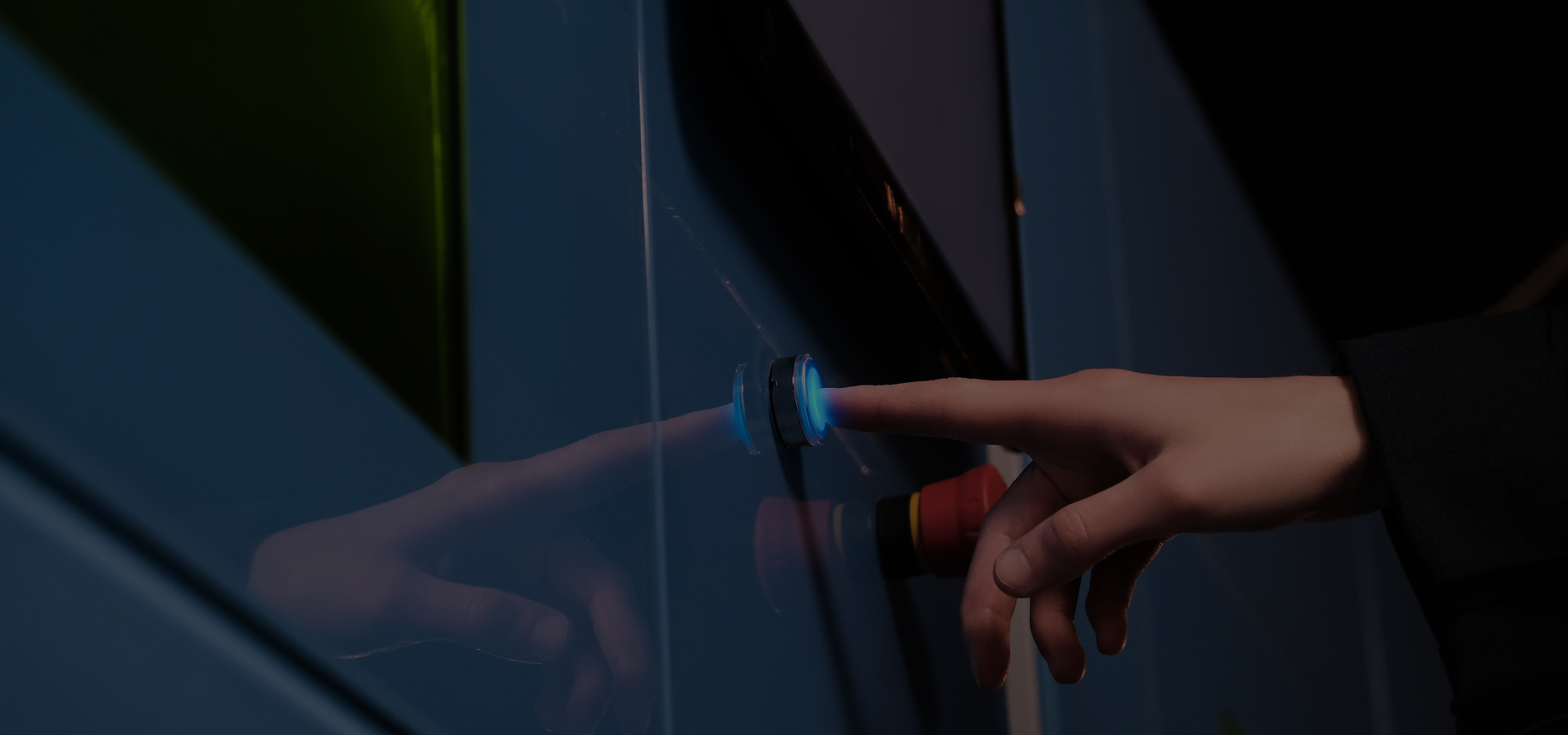

Process initiation

Once the 3D model is ready and adapted, processed by the slicer, we load it into the SLM printer using a flash drive or via WiFi network.

Additionally, it's necessary to load the printer with material. If printing is done using a single alloy, there's no need to load powder every time. The machine will use powder from its own supply. Just press the button and start the printing process.

If printing parts from different alloys is planned, the powder will need to be replaced. After initiating, the SLM printer will automatically calibrate the laser system, fill the chamber with inert gas, and sensors will monitor the safety and accuracy of the operation

Additionally, it's necessary to load the printer with material. If printing is done using a single alloy, there's no need to load powder every time. The machine will use powder from its own supply. Just press the button and start the printing process.

If printing parts from different alloys is planned, the powder will need to be replaced. After initiating, the SLM printer will automatically calibrate the laser system, fill the chamber with inert gas, and sensors will monitor the safety and accuracy of the operation

User-friendliness

We have created a product that offers convenience and simplicity in its use. This is hinted at by the minimalist design of our 3D printers.

There's no need to stand in the workshop to set up the printing. Most of the work is done with a cup of coffee at the computer. Moreover, one person can operate multiple SLM setups simultaneously

There's no need to stand in the workshop to set up the printing. Most of the work is done with a cup of coffee at the computer. Moreover, one person can operate multiple SLM setups simultaneously

Please send your inquiry to learn more about our SLM 3D printers

Do you have any questions about our printers or contract printing services? Our knowledgeable specialists will promptly answer all your inquiries

Step 5

3D printing

Step 6

Post-processing

Areas of application

Learn about the advantages of metal 3D printing for various manufacturing sectors

Learn more!